Things about Prototype Machining Services For Production Development

Prototype - American Wire EDM - Prototype Stamping for Dummies

Once the G-code is sent out to the machine, very little manual guidance is required, because the device understands when and where to cut and carries out the machining autonomously. This results in considerable time and expense savings when compared to traditional machining, in which an experienced machinist cuts the workpiece utilizing manually operated cutting tools.

Pros and Cons of Prototype Machining

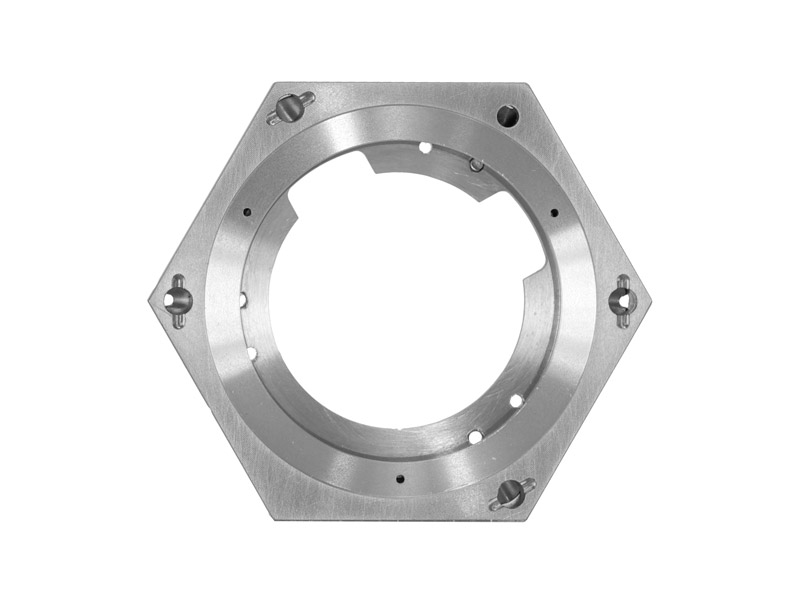

Unlike additive production, in which a 3D printer deposits product in layers to form a things, CNC machining involves cutting sections away from a formless block referred to as the "workpiece." Excess product is disposed of or recycled, ultimately leaving a completed part. More complex CNC machines, those with a higher number of axes, are capable of cutting the workpiece in more intricate ways, producing parts with more complex geometries.

Although many now consider 3D printing to be the dominant type of rapid prototyping, CNC machining is likewise an important process for creating model parts. To comprehend why, it is beneficial to think about the various forms a prototype can take, and to think about why these prototypes exist. Prototypes can have many different functions.

CNC Prototype Machining: Everything You Need to Know - RapidDirect Blog

FMD Prototype Machining - Truths

These looks-like models may be utilized to assist the R&D process or offer evidence of principle. If made to a high aesthetic requirement, they may likewise be used to pitch a brand-new product to possible financiers. Such models can be really essential, but they do not always require to be used high-end expert equipment: they might be crafted by hand or printed with a low-end desktop 3D printer.

Depending on the phase of product development, companies may need to produce engineering prototypes or production prototypes: prototypes that not only appear like the last part, but function like it too, serving as a substitute as near as possible to the genuine thing. While 3D printing might be an excellent choice for looks-like prototyping, CNC machining is typically more suitable for these functional models that require strength, mechanical stability or other qualities not paid for by additive processes.

CNC machining can be an exceptional choice for prototyping, but its viability depends on the nature of the model. For what function will the model be used? From what Full Article will it be made? And from what material will the final part be made? These and other concerns will ultimately assist the user to the most suitable method of prototyping.